11kV High Voltage Porcelain Fuse cutouts CTF-A

Application

The primary purpose of any Fuse cutouts is to provide protection to the lines of your system and the various apparatus on those lines such as transformers and capacitor banks. Fuse cutouts provide reliable protection from low-level overloads that just melt the fuse link, intermediate faults, and very high faults, through maximum intermupting capacity.

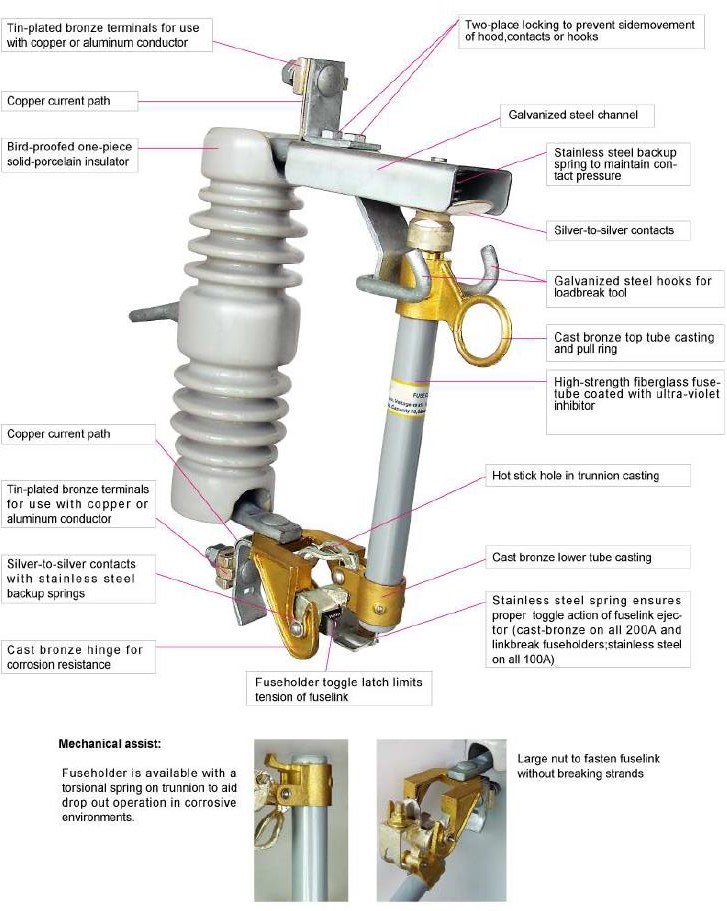

Quality Construction

-Top Contact

The top contact is attached to the galvanized-steel hood by a stainless rivet to provide a smooth self-aligning action during closing even in severely corrosive environments. The top contact provides a socket-type cavity for latching the fuse holder and prevents any possible "over-travel. of the fuse holder. The top contact is made of a highly conductive copper strip with silver-plated embossments to resist corrosion. The contacts are held under constant pressure designed to maintain firm contact with the fuse holder contact surface until fault interruption is accomplished.

-Hinge

The hinge on the Fuse cutout employs large pivot areas for the fuse holders trunnion and is cast of a copper alloy chosen for its strength and corrosion resistance. The hinge contacts are highly conductive copper alloy stampings and are plated to assure low resistance current transfer from the trunnion casting. The parallel current paths are backed up by high strength cantilever springs and are riveted to the hinge castings. Fuse holder can be dropped into place and easily lifted up and out. No tricky maneuvering.

-Fuse holder

The solid cap on the single vent fuse holder is a copper alloy, silver-plated to provide efficient current transfer. An integral ring is provided in the top tube casting for opening and closing the fuse holder with conventional disconnect tools from the ground, from a bucket truck or from the pole.

The toggle type trunnion casting is a selective silver-plated bronze for efficient current transfer to the lower hinge contacts.A cam shaped projection on each side of the trunnion casting provides high pressure parallel current paths to the lower contacts. These projections, or pivot pins, are cast full round for smooth rotational operation in the hinge. The link ejector assists in arc interruption during low fault current or exces-sive overload conditions. A groove in the center of the link ejector allows the fuse link's pigtail to go directly from the fuse tube to the attachment nut.A curved ejector minimizes bending stresses in the pigtail to prevent broken strands.A stainless steel torsion spring on the linkejector helps to rapidly eject the link from the bore of the fuse holder during interruption. The 200 ampere link ejector has a wider groove area and increased spring force to accommodate the larger links.

-Fuse tube

The 1/2-inch inside diameter of the Fuse cutouts 100ampere fuse tube increases internal pressure giving superior and reliable expulsion action. During frequently encountered intermediate fault ranges this diameter also permits higher TRV(transient recovery voltage) values to be tolerated. This small bore design eliminates any concerm related to high impedance phase-to-phase faults on ungrounded wye and delta systems.

The inside liner is constructed of a synthetic arc-quenching material. The tube is made of fiberglass which permits the smaller bore and provides a higher burst strength. It is protected from the weather and environment by a special ultra-violet resistant coating.

Also, the fuse tube operates with fuse links from all major suppliers.

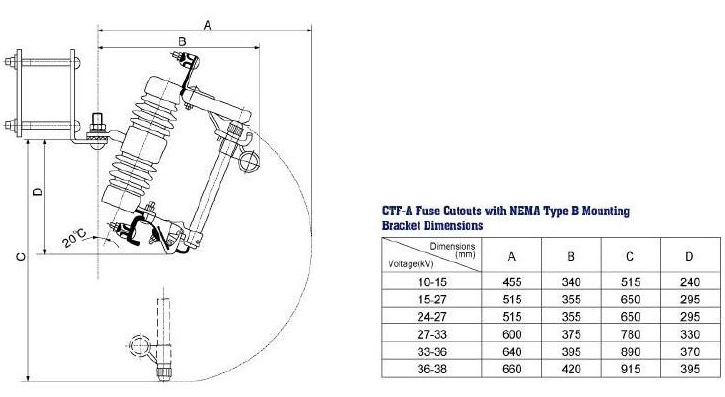

Mounting Bracket

Fuse cutouts come packed one per carton including a NEMA Heay Duty “B” bracket with captive “11/2” bolt for cross arm mounting. Type "X" bracket, also for cross arm mounting, provides “25/8” additional clearance between the cross arm and the cutout.

Higher Interrupting Capacities

By using a copper arc shortening rod inside the top of the fuse tube, higher interrupt ratings are obtainable. An arc shortening rod is attached to the cap of some fuse tube and lowers the fuse link within the fuse tube. This permit a much shorter arc. resulting in less arc energy, and higher interrupling capacities.

For 200 A tubes, it allows for full voltage rating. It is necessary to use fuse links with removable button heads when arc shortening rods are employed.

Parts Designation of Fuse Cutouts for Type CTF-A

Table C1-Main Technical Parameter of Fuse Cutouts

Type CTF-A

| Manufacturer | Haibian Power Equipment Co., Ltd. | |||||||||||||

| Type designation | CTF-A | |||||||||||||

| Rated voltage (Ur) | kV | 10-15 | 15-27 | 24-27 | 27-33 | 33-36 | 36-38 | |||||||

| Rated current (Ln) | kA | 100 | 200 | 100 | 200 | 100 | 200 | 100 | 200 | 100 | 200 | 100 | 200 | |

| 1 | General Feature | Unit | ||||||||||||

| 1.1 | -Housing material | Porcelain | Porcelain | Porcelain | Porcelain | Porcelain | Porcelain | |||||||

| 2 | Ratings & characteristics | |||||||||||||

| 2.1 | -Rated frequency | Hz | 50/60 | 50/60 | 50/60 | 50/60 | 50/60 | 50/60 | ||||||

| 2.2 | -Interrupting capacity | kA | 10.0 | 12.0 | 10.0 | 12.0 | 8.0 | 10.0 | 6.3 | 8.0 | 6.3 | 8.0 | 6.3 | 8.0 |

| 3 | Housing insulation level | |||||||||||||

| 3.1 | -Power frequency withstand voltage (Dry) | kV | 40 | 40 | 45 | 45 | 65 | 65 | 70 | 70 | 72 | 72 | 75 | 75 |

| 3.2 | -Power frequency withstand voltage (Wet) | kV | 30 | 30 | 35 | 35 | 50 | 50 | 55 | 55 | 56 | 56 | 60 | 60 |

| 3.3 | -Lightning impulse withstand voltage ( BIL) | kV | 110 | 110 | 125 | 125 | 150 | 150 | 170 | 170 | 170 | 170 | 180 | 180 |

| 4 | Creepage distance | mm | 250 | 250 | 350 | 350 | 530 | 530 | 700 | 700 | 720 | 720 | 850 | 850 |

| 5 | Package data | |||||||||||||

| 5.1 | -Net weight of each unit | Kg | 7.0 | 7.1 | 8.3 | 8.4 | 10.0 | 10.1 | 15.0 | 15.1 | 15.5 | 15.6 | 17.0 | 17.1 |

| 5.2 | -Dimensions(1PC/CTN) | cm | 41×31×11 | 49×35×12.5 | 49×35×14 | 50×38×14.5 | 57×38×14.5 | 61×38×14.5 | ||||||

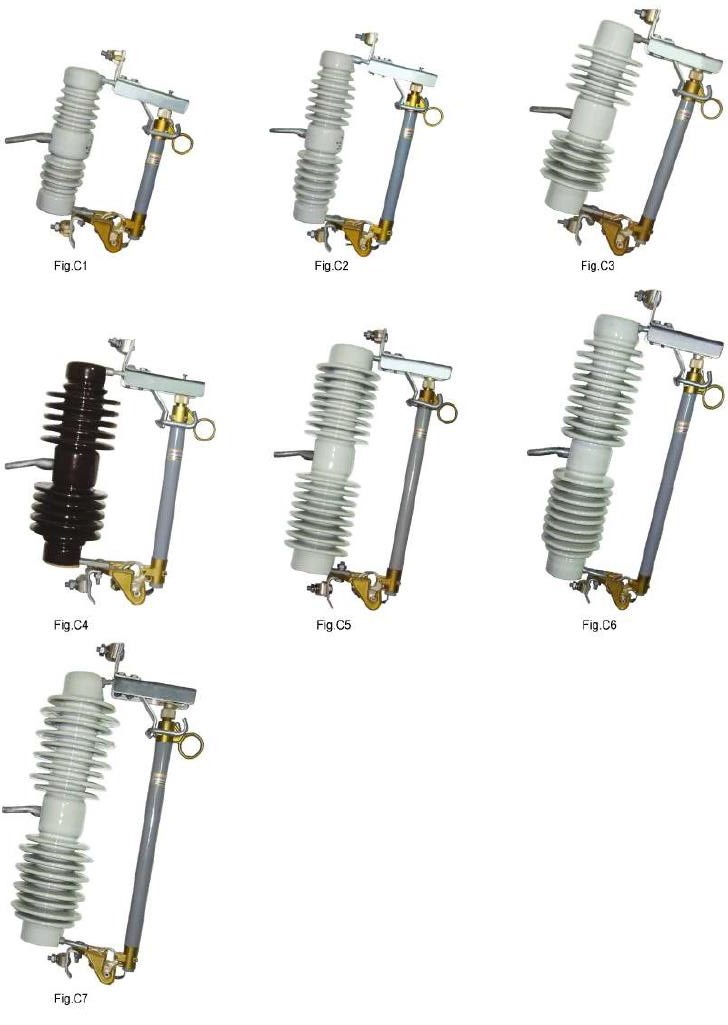

| 6 | Figure No. | Fig.C1 | Fig.C2 | Fig.C3/Fig.C4 | Fig.C5 | Fig.C6 | Fig.C7 | |||||||